| API 5L/A53 GR.B, ERW Steel Pipe, Carbon Steel | ||||||

| Outside Diameter 外径(mm) | Wall Thickness 壁厚 (mm) | Length 长度 (mtr) | Quantity 数量 | REMARK 标记 Surface, End | EXW CHINA 出厂价 USD/TON 美金每吨 |

|

| PCS 根数 | TON 吨位 | |||||

| 152 | 4.50 | 6 | 500 | 49.10 | Bare,PE | $459.49 |

| 33.4 | 3.80 | 6 | 820 | 13.65 | $463.59 | |

| 33.4 | 3.00 | 6 | 532 | 7.18 | $454.02 | |

| 42.3 | 4.25 | 6 | 123 | 2.94 | $478.63 | |

| 48.3 | 4.00 | 6 | 22 | 0.58 | $478.63 | |

| 60.3 | 4.00 | 6 | 236 | 7.86 | $497.78 | |

| 76.1 | 4.50 | 6 | 622 | 29.65 | $449.91 | |

| 88.9 | 4.75 | 6 | 63 | 3.73 | $449.91 | |

| 108 | 4.50 | 6 | 256 | 17.64 | $441.71 | |

| 219 | 7.80 | 6 | 36 | 8.77 | $464.96 | |

| 33.4 | 3.38 | 984 | 164 | 2.46 | Bare | $453.40 |

| 42.2 | 3.56 | 180 | 30 | 0.61 | $461.67 | |

| 48.3 | 3.68 | 330 | 55 | 1.34 | $452.02 | |

| 60.3 | 3.91 | 150 | 25 | 0.82 | $442.38 | |

| 73 | 5.16 | 180 | 30 | 1.55 | $463.05 | |

| 88.9 | 5.49 | 54 | 9 | 0.61 | $468.56 | |

| 114.3 | 6.02 | 324 | 54 | 5.21 | $447.89 | |

| 168.3 | 7.11 | 120 | 20 | 3.39 | $454.78 | |

| 219.1 | 8.18 | 48 | 8 | 2.04 | $454.78 | |

| 273 | 9.27 | 240 | 40 | 14.47 | $485.10 | |

| Note: 1. The above price is based on bare pipe, for extra coating, please contact sales@primesteeltube.com; 2. The above price is based on EXW, for FOB/CIF/CFR price, please contact sales@primesteeltube.com; 3. The above price is not including any packing and end processing charge, for detailed quotation, please contact sales@primesteeltube.com; 4. The above price is only valide during August 27- September 3; 5. The applicapable MOQ for this price list is over 100 tons; |

||||||

HUNAN PRIME STEEL PIPE is the export gateway of SHINESTAR HOLDINGS GROUP. We are dedicated in providing and exporting high performance-price ratio welded & seamless steel pipes and fittings covering various steel grades. At Prime Steel Pipe, we believe that honest communication, expertise in our industry, and prompt execution lead to strong long-term relationships.

2016/08/26

Prime Updated In Stock ERW Steel Pipe Price List 2016/08/20

Quenching of ERW Steel Pipe

ERW steel pipe surface heat treatment is usually heated by induction heating or flame way. The main technical parameters is surface hardness, local hardness and effective case depth. Vickers hardness test hardness can also be used Rockwell hardness (hrc) or surface. Test Force (ruler) of choice and effective hardened layer depth and surface hardness Longitudinal relevant. This involves three kinds of hardness.

Vickers hardness test is an important means of heat Longitudinal surface hardness, it can be used to test power 0.5 ~ 100kg test thin 0.05mm thick surface hardening layer, which is the highest accuracy, the surface treatment of the workpiece can be distinguished small differences in hardness. In addition, the effective case depth gauge should be detected by the Vickers hardness, so the surface for heat processing or heavy use of surface heat treatment Hunan Longitudinal unit, equipped with a Vickers hardness tester is necessary.

Superficial Rockwell hardness tester is very suitable for testing the hardness of the workpiece surface hardening, surface Rockwell hardness scale, there are three to choose from. You can test the effective hardening depth of more than 0.1mm Longitudinal various surface hardening. Although the surface Rockwell hardness of Vickers hardness tester accuracy is not high, but as the heat treatment factory quality management and testing tools qualified inspection, has been able to meet the requirements. Moreover, it also has a simple, easy to use, low price, rapid measurement can be read directly hardness and other characteristics, the use of surface Rockwell hardness of surface heat treatment can batch-by-piece Hunan Longitudinal rapid non-destructive detection . This is for the lake seam welded pipe processing and machinery manufacturing plants is important.

If you require a higher hardness of parts locally, induction heating, etc. are available locally hardening heat treatment, such Longitudinal usually mark the location and the local partial quenching hardness values ??in the drawings. Longitudinal hardness testing to be carried out within the designated area. Hardness testing instruments can be used Rockwell hardness test HRC hardness values, such as heat treatment hardened layer is shallow, may be surface Rockwell hardness testing HRN hardness value.

We are manufacturer of Carbon Steel Pipes and supply high quality Carbon Steel Pipes in both large and small quantities worldwide & offer you the best prices in the market.

We have a team of experienced professionals with years of experience in manufacturing.

The Working Safety on the Scaffolding Structure

Scaffolding safety problem has always been one of the most concerned topic for the broad masses of users, scaffolding after put into use, be sure to practice, pay attention to safety.

1.Clean fall at any time should be paid attention to when working on the scaffolding materials, keep the building scaffolding the neat and clean, do not heap of materials, tools, lest affect safe operation or occur off cuts.

2. When making pry, pull and push operation, attention should be paid to take the correct posture, fasten your seat belt, wary of instability of body fall, fall, or put things out. On the construction scaffolding dismantling templates, the bracket of necessary measures should be taken to, in case of removed material fall outside the frame.

3. When building scaffold surface height is not enough, need padding, must take the stable and reliable way to, and shall not exceed 1250 high cushion, heightening the safety protection facilities at the same time; When more than 1250 must design according to the application for examination and approval.

4. Through carrying on the construction scaffolding material is homework personnel, to signal to remind others in time, the material to put light shelf stability, forbid to use the dumping, slammed him or other means of discharging in a hurry. . Ban playing on the construction scaffolding, go to bed, or sitting down to rest on a rod, and shall not be controlled and run and jump, give way to each other to keep the body balance.

We are manufacturer of Carbon Steel Pipes and supply high quality Carbon Steel Pipes in both large and small quantities worldwide & offer you the best prices in the market.

We have a team of experienced professionals with years of experience in manufacturing.

2016/08/25

The Uses of Seamless Carbon Steel Pipe

A seamless carbon steel pipe has many uses, thanks to the tough and versatile nature of carbon steel. This pipe is seamless, so it tends to have better durability and strength, making it useful for construction work. Many heat-transfer systems use a seamless carbon steel pipe network to the hot or cold liquid or gas in an area. The petroleum industry uses this pipe to carry large amounts of petroleum from the ground to the surface, and this pipe also is commonly used to transfer the petroleum to other places. This pipe is easier to form and bend than other carbon steel pipes, so it also can be used in places where custom angles and shapes are needed.

Many large structures use pipes in the deep foundation, the section that is underground. If a seamless carbon steel pipe is used, then it is driven into the ground by a large machine and may be filled with concrete after it is pile-driven to protect the pipe and make it even sturdier. This type of pipe generally is very durable and does not bend easily from stress, so it is uniquely suited for deep foundations.

Heat transfer systems are used in many structures, and one way to carry the heat around the structures is with a seamless carbon steel pipe. A fluid or gas, such as hot water or steam, normally is sent through the pipe and travels the length of the structure. The steel is corrosion resistant, and the lack of seams further protects this pipe from warping during use, so this pipe commonly is used for this purpose.

Similar to a heat-transfer system, the petroleum industry typically will use a seamless carbon steel pipe to transfer petroleum. This pipe typically is much larger than carbon steel pipes used for other purposes to allow the pipe to carry the large amount of petroleum. Depending on where the pipes are positioned, they can be used to carry the petroleum from the earth into a holding tank, or from tank to tank.

We are manufacturer of Carbon Steel Pipes and supply high quality Carbon Steel Pipes in both large and small quantities worldwide & offer you the best prices in the market.

We have a team of experienced professionals with years of experience in manufacturing.

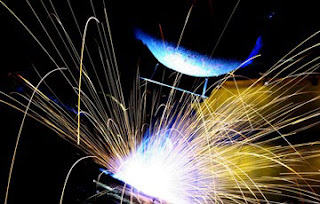

High Frequency Welding

High Frequency (HF) or Radio Frequency (RF) welding is the joining of materials by supplying HF energy in the form of an electromagnetic field (27.12 MHz) and pressure to the material surfaces to be joined. A generator produces the energy. The tool used to supply the

energy is called an electrode. The electrical energy causes the molecules within the material to start moving, which generates heat that causes the material to soften and thereby fuse together. No outside heat is applied. It is instead generated within the material. After cooling the welded surface under maintained pressure, the material is fused and a weld has been created. The weld seam can be at least as strong as the surrounding material – or even stronger.

Four important factors that affect the final weld result are pressure, welding effect, welding time and cooling time. These parameters can be adjusted and combined in different ways to achieve the optimal welding result for a specific material.

The material most commonly used with HF welding is PVC (polyvinyl chloride), sometimes called vinyl and PU (Polyurethane). The material can be thick or thin, reinforced or coated. It can also be plain, coloured or patterned.

We are manufacturer of Carbon Steel Pipes and supply high quality Carbon Steel Pipes in both large and small quantities worldwide & offer you the best prices in the market.

We have a team of experienced professionals with years of experience in manufacturing.

2016/08/24

World Steel Pipe Industry

This report offers historical demand data (2004, 2009 and 2014) plus forecasts (2019 and 2024) by application for six world regions and 19 major countries. The study also considers market environment factors, examines the industry structure, evaluates company market share and profiles 25 industry players worldwide.

World demand to rise 3.5% annually through 2019

Global demand for steel pipe is forecast to advance 3.5 percent per annum through 2019 to 79.7 million metric tons, with growth paced by continued strong increases in developing markets. The pace of gains will decelerate from that of the 2009-2014 period as construction activity slows in China and numerous other developing countries, and oil and gas exploration moderates in North America after a period of rapid growth.

Equipment manufacturing market to see fastest gains

The oil and gas market is the dominant application for steel pipe. Steel makes up the vast majority of pipe used in oil and gas transportation and especially production due to its high strength and pressure and thermal resistance. Demand for oil and gas pipe saw healthy growth between 2009 and 2014, driven by growth in China and North America; however, advances are expected to decelerate because of slowing exploration and drilling due to already high production and lower oil prices.

Steel pipe used in equipment manufacturing is expected to see above-average growth through 2019. Although efforts to simplify automotive manufacturing and reduce the weight of finished products will check more robust demand advances, continued expansion in durable goods manufacturing will support strong growth. Structural steel will also see growth above the global average through 2019. Although slowing expansion in the oil and gas market (as structural steel pipe is often used in well construction) will limit advances, construction spending growth will drive demand.

Steel pipe also sees significant usage in construction markets, where it is used in a variety of applications, such as conduit, sewer, and drainage. However, unlike the oil and gas market, steel exhibits lower penetration in most applications due to price and performance advantages of other materials such as plastic.

Growth in China to slow but remain above global average

China, by far the world's largest national market, with 30 percent of global demand in 2014, was a primary driver of demand growth for steel pipe between 2004 and 2014. Expansion across all steel pipe markets, especially in OEM, structural, mechanical, and construction applications, sparked global steel pipe demand.

We are manufacturer of Carbon Steel Pipes and supply high quality Carbon Steel Pipes in both large and small quantities worldwide & offer you the best prices in the market.

We have a team of experienced professionals with years of experience in manufacturing.

Labels:

steel pipe,

steel pipe industry trend

2016/08/22

Checking Flanges Regularly

Flange connection refers to the two pipe, pipe fittings or equipment, the first of their fixed in a flange plate, the two flange, with the pad, with bolts to fasten them together, complete the connection. Some pipe products and equipment have own flange plate, also belong to the

flange connection. Flange is divided into threaded flange and welding flange, it is a kind of disk shaped parts, in the pipeline project is the most common, the flange is used in pairs. In the pipeline project, the flange is mainly used for the connection of the pipe. In the need to connect the pipe, a variety of installation of a flange plate, low pressure pipe can be used wire connection flange, 4 kg or more pressure on the use of welding flange. Low voltage and small diameter wire connecting flange, high pressure and low pressure and large diameter are welded flange, the thickness of the flange plate of different pressure and the connecting bolt diameter and the number is different. Flange is not produced corrosion, pitting, corrosion or wear, and is one of the highest strength of the materials used in building materials. Because the stainless steel has good corrosion resistance, so it can make structural components to maintain the integrity of Engineering design.

Flanges can not be stored for a long time, should be regularly inspected, often on the exposed machined surfaces shall be maintained in a clean, remove dirt, neatly stored in indoor and ventilated and dry place, stacked or open storage is prohibited. Flange of the ball valve, globe valve, gate valve is used, only for fully open or fully closed, do not agree to do to adjust the flow, so as to avoid the sealing surface by erosion, accelerated wear and tear. Materials of the flange is convenient, simple manufacture, low cost, wide use; but less rigid. Therefore, it cannot be used for supply and demand, flammable, explosive and high vacuum degree requirements of chemical process piping system and height, is extremely harmful to the occasions. Seal type plane and surface process. The flange has the advantages of simple structure, small volume, light weight, compact and reliable, the current valve sealing surface material widely used plastic, sealing, in the vacuum system has also been widely used; easy maintenance, valve structure is simple, seals are generally activities, the removal of the replacement is more convenient; in the fully open or fully closed, the ball and seat sealing surface and the dielectric isolation.

We are manufacturer of Carbon Steel Pipes and supply high quality Carbon Steel Pipes in both large and small quantities worldwide & offer you the best prices in the market.

We have a team of experienced professionals with years of experience in manufacturing.

Casing pipe

Steel Casing pipes, which are used for casing of oil and gas. Casing pipes are manufactured of metal in-house produced and smelted in the electric furnace, treated with synthetic slags and cast by continuous casters. The applied steel making process ensures the achievement of chemically pure steel with reference to sulphur and phosphor contents providing high tensile, ductility and corrosion resistance properties of pipes to be operated at low temperatures in various corrosion media.

Automatic ultrasonic and electromagnetic nondestructive inspection is performed to detect pipe outside and inside flows. Inspection of pipe ends before threading and couplings after treading is realized by magnetic-fluoroscopic flaw detection. Rolling using a press piercing mill and continuous mill equipped with a fixed mandrel allows strict measurement tolerances to be obtained and ensures a lack of pipe body and surface flows. Wall thickness is inspected throughout the pipe length by the ultrasonic unit.

Pipes are heat-treated in a computerized walking beam furnace. Steel grades and heat treatment regimes applied allow high-strength pipe to be obtained.

Threading of pipes and couplings is performed by numerical control machine tool. The facilities allow the production of both standard ("Buttress") and up-to-dated high-sealed threads of "Premium" type. Every threaded pipe end and every coupling is controlled with a thread gauge.

Rolling using a press piercing mill and continuous mill equipped with a fixed mandrel allows strict measurement tolerances to be obtained and ensures a lack of pipe body and surface flows. Wall thickness is inspected throughout the pipe length by the ultrasonic unit.

We are manufacturer of Carbon Steel Pipes and supply high quality Carbon Steel Pipes in both large and small quantities worldwide & offer you the best prices in the market.

We have a team of experienced professionals with years of experience in manufacturing.

Labels:

casing pipe,

steel casing pipe

Tenacious Struggle! Women's Volleyball Spirit Shines Shinestar Forward

Rio Olympics, Lang Ping and her volleyball girls won the most exciting gold medal. Almost can not qualify in the group stage, but they took on a new look with a few days, and continuous defeat their opponents to win the Champions. This is a rare miracle in the Olympic history. This is a perfect portrayal of sports spirit, called Epic Olympic.

More important than a gold medal, women's volleyball team don't give up, tenacious, unity and struggle, very strongly arouse whole society of national pride,activation of the 80's of the 20th century legends of the fall collective memory, gather up the lofty spirit of the value of certain consensus.

Since the last century 80's birth, women's volleyball team spirit beyond the sport, inspired people from all walks of life. To return to the stage of world sport of China sports, In just a few years, it has cast a master of the women's volleyball team.To return to the global modernization journey of China, 30 years time becomes the world's second largest economy. Wonders of the women's volleyball, women's volleyball team spirit, as a pioneer, as an example, inspired the Chinese miracle, shaping the spirit of the Chinese to become era of reform and opening up the national spirit of the component and the kernel symbol.

Today, Shinestar in the stage of globalization is make unremitting effort to continue to promote enterprise growth, to create a platform for employees and realize the value, solve problems, create value for customers, and ultimately create "benchmarking enterprise" in one hundred in the field of steel overall service goal. In this period, the road of enterprise is the same as the prospect of the China women's volleyball before Olympic.. Have a certain strength, but also full of uncertainty. The Key is to see how to realize yourself, to have self-confidence, enough cohesion and fighting!

The spirit of the Chinese women's volleyball team persist, courage and hard work is Shinestar Group guide of beacon. Shinestar Group after 23 years of tempered, built on the basis of quality production, integration service as guarantee, the globalization trade as the engine of the perfect platform. Twenty-three years, Shinestar talent never retreat, always forward, based from Changsha, deep tillage hunan province, to the national layout, to go global, each step of the development are powerful. In the tempered, Shinestar Group now has 15 subsidiaries, service penetration to production, procurement, sales, processing, logistics, business to go global, domestic and international, and has been widely accepted by the customers, partners, employees and society, continuously realizing the business from good to excellent forward.

A country, the historical process of an enterprise, hard to avoid winding ups and downs, but we can not lose, is connected by blame condensation of frame of mind, is struggle more than the spirit of struggling ambition. For our Shinestar feelings in, in the spirit, the position of courage to face the difficulty, have done accurately the outcome between the top is conscious of the competitiveness of has again hit high hope and possibility. We have reason to believe that, in the women's volleyball team spirit, under the stimulus of Shinestar of tomorrow will create more miracles.

Labels:

women's volleyball spirit

Packing and Shipping of ERW Steel Pipe

Plastic closes both ends, hexagonal bundles maximum 2.000kg with several steel strips, two bags on each bundle, wrapped in waterproof paper, PVC sleeve, and IN in sackcloth with several steel strips, plastic caps.

Both ends with each crate will indicate the order No., heat No., dimensions, weight and bundles or as requested. We can also offer customized packing for ERW steel pipes as per customer requirement.

Overseas packaging

Export packaging is geared towards the protection, handing and transport of ERW steel pipes by air or sea freight and, as such, shares many characteristics wth export and transport packaging. Utmost care must also be taken to make overseas packaging suitable for long periods of storage. It is important for overseas packaging to be designed with ease of handling in mind, so as to ensure ERW steel pipes is treated with the utmost care at all times.

Subscribe to:

Posts (Atom)