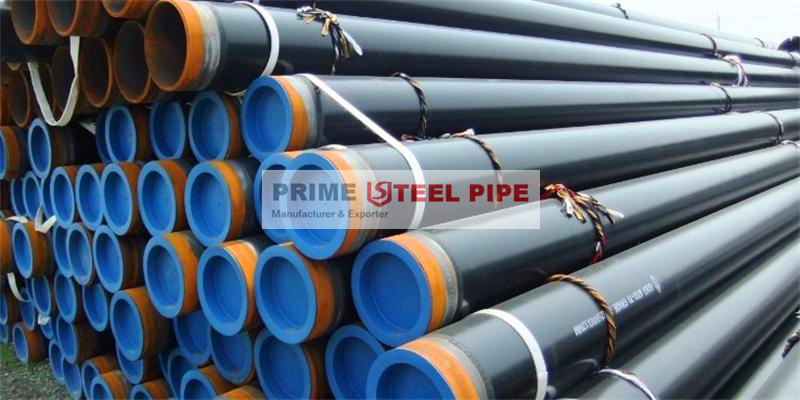

Standard: ASTM A53 GR.B/API 5L GR.B/ASTM A106 GR.B

Specification: 609.6mm*9.53mm*5800mm

Surface: Black Painted

Ends: Bevelled

Quantity: 264 Tons

Production Time: 30 days info@primesteeltube.com

HUNAN PRIME STEEL PIPE is the export gateway of SHINESTAR HOLDINGS GROUP. We are dedicated in providing and exporting high performance-price ratio welded & seamless steel pipes and fittings covering various steel grades. At Prime Steel Pipe, we believe that honest communication, expertise in our industry, and prompt execution lead to strong long-term relationships.

| Standard | Out Diameter | Tolerance of Pipe End | Tolerance of Pipe Body |

| API 5L |

219.1~273.1

| +1.6mm, -0.4mm | ±0.75% |

| 274.0~320 | +2.4mm, -0.8mm | ±0.75% | |

| 323.9~457 | +2.4mm, -0.8mm | ±0.75% | |

| 508 | +2.4mm, -0.8mm | ±0.75% | |

| 559~610 | +2.4mm, -0.8mm | ±0.75% |

| Standard | Grade | Out Diameter | Wall Thickness |

| API 5L | A | 219.1~457 | +15%, -12.5% |

| B | 508~610 | +17.5%, -12.5% | |

| X42-X80 | 508~610 | +19.5%, -8% |

| Standard | Class | Grade | Chemical Analysis(%) | Mechanical Properties(min)(Mpa) | ||||

| C | Mn | P | S | Tensile Strength | Yield Strength | |||

| API 5L | PSL1 | B | 0.26 | 1.20 | 0.030 | 0.030 | 414 | 241 |

| X42 | 0.26 | 1.30 | 0.030 | 0.030 | 414 | 290 | ||

| X46 | 0.26 | 1.40 | 0.030 | 0.030 | 434 | 317 | ||

| X52 | 0.26 | 1.40 | 0.030 | 0.030 | 455 | 359 | ||

| X56 | 0.26 | 1.40 | 0.030 | 0.030 | 490 | 386 | ||

| X60 | 0.26 | 1.40 | 0.030 | 0.030 | 517 | 414 | ||

| X65 | 0.26 | 1.45 | 0.030 | 0.030 | 531 | 448 | ||

| X70 | 0.26 | 1.65 | 0.030 | 0.030 | 565 | 483 | ||

| PSL2 | B | 0.22 | 1.20 | 0.025 | 0.015 | 414 | 241 | |

| X42 | 0.22 | 1.30 | 0.025 | 0.015 | 414 | 290 | ||

| X46 | 0.22 | 1.40 | 0.025 | 0.015 | 434 | 317 | ||

| X52 | 0.22 | 1.40 | 0.025 | 0.015 | 455 | 359 | ||

| X56 | 0.22 | 1.40 | 0.025 | 0.015 | 490 | 386 | ||

| X60 | 0.22 | 1.40 | 0.025 | 0.015 | 517 | 414 | ||

| X65 | 0.22 | 1.45 | 0.025 | 0.015 | 531 | 448 | ||

| X70 | 0.22 | 1.65 | 0.025 | 0.015 | 565 | 483 | ||

| X80 | 0.22 | 1.85 | 0.025 | 0.015 | 621 | 552 | ||