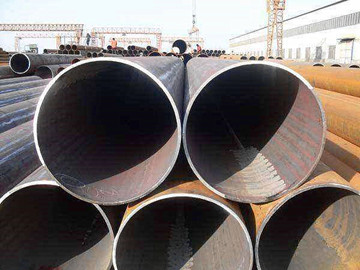

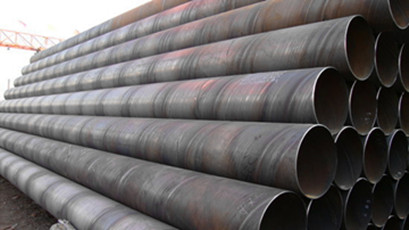

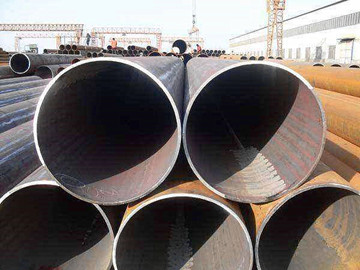

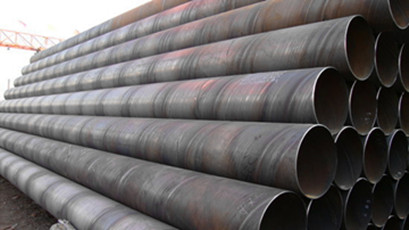

LSAW Steel Pipe and SSAW Steel Pipe are in the category of welded carbon steel pipe. And both type of pipes can be applied for structure support, pipe piling and liquid transmission. The difference between LSAW Steel Pipe and SSAW Steel Pipe are as follows.

1.Submerged Arc Welding Process Difference.

Compared with spiral submerged arc welding process, longitudinal submerged arc welding process can inevitably have a lot of T-weld, so the existence of welding defects has great increased. The welding residual T-welds stress is large, and the weld metal are often in three-dimensional stress state which can increase the likelihood of cracks. Besides, according to the provisions of submerged arc welding process, each weld shall have the arc at the place and extinction. However, in each longitudinal submerged arc welding ring, it is unable to meet the conditions which causes more weld defects during longitudinal submerged arc welding process.

2.Production Range Difference

Under the same operating pressure to produce the same outside diameter longitudinal weld pipe and spiral weld pipe, spiral weld pipe can produce thinner wall thickness pipe than longitudinal weld pipe. Because when the pressure in the pipe to withstand, it typically produces two main stress on the pipe wall. These two main stress are radial stress and axial stress. On spiral weld pipe, these two main stress are divided by the helix angle of the weld, therefore synthetic spiral weld stresses are the main stress.

3.The Hydro Static Burst Strength

The yield stress and burst pressure on spiral weld pipe is lower than the longitudinal weld pipe, even though there are certain relevant comparison test has says the yield pressure and burst pressure measured and theoretical values are basic the same on spiral and longitudinal weld pipe. In the blasting test, it also proved that the hoop blasting mouth deformation rate for spiral weld pipe is significantly greater than the longitudinal weld pipe. It confirmed that spiral weld pipe has a greater plastic deformation than longitudinal weld pipe.

4.Toughness Difference

Compared with the same specification spiral weld pipe and longitudinal weld pipe, spiral weld pipe has a higher impact of toughness. With the increasing needs for large diameter pipe with high strength and with the development of new steel grades, It requires greater ductile fracture tip.

5.Fatigue Strength Difference

With the same test data in the same area, under the same pipe distribution and resistance, longitudinal submerged arc weld pipe has a higher level of fatigue strength. Because of the transfer pipeline output volume changes, in the actual operation, the pipe is subjected to random alternating loads of action. It is very significant to judge the life of pipeline by learning the cycle fatigue strength of steel.

LSAW Steel Pipe will occur different forms of damage within a certain time, due to the use conditions and the different application environment, as well as objective conditions changes over time and few uncontrolled pipe defects.

Hydrogen Induced Cracking (HIC) refers a type of cracking occurs when LSAW Steel Pipe containing hydrogen suffers sufficiently high applied stress or residual stress. HIC happened when the hydrogen diffusion into the interior of the parent metal, in solid solution or in the presence of a metal hydride form. This is a potential pipe damage reason. When the pipes are used in the underground, buried deep under the higher stress or pressure, sometimes in a few weeks or even few days, the pipe can occur hydrogen induced cracking.

When the pipe contact with hydrogen or a cathodic corrosion reaction, the hydrogen atom will enter into the metal pipe inside organization. Therefore, the material becomes brittle pipe. However, the pipe material will not necessarily lose ductility cracking. If apply appropriate heat treatment for the LSAW Steel Pipe, either online or offline heat treatment process, the hydrogen will out of the base material from the interior of the pipe. After this process, some of the material will restore the original strength.

Difference between hot stretch reducing pipe and LSAW steel pipe are basically has the following two points:

1, Resulting in differnce on product quality due to the different processes, hot stretch reducing also carried out a process after high-frequency welding process that lsaw steel pipe can not found ------ Longitudinal are no clear line inside and outside burrs. Burr presence will affect the tube fluid - flow, burr block the normal flow of fluid, resulting in a whirlpool. According to principles of fluid mechanics, welding must increase local compression, discontinuity make pipe safety factor is also greatly reduced, hot stretch reducing steel production process - fully taken into account the existence of the risk of burrs, to limit burr removal, making it uniform thickness, no difference in the appearance and seamless. So from this point of view, hot stretch reducing pipe joints also completed the transition seamless.

2, Weld quality directly determines the quality of welded pipe, seamless pipe is welded with the greatest difference lies. Longitudinal after the high-frequency welding, straight seam set carbon can not be eliminated, weld and the parent just join together and not completely fused into one - could not stand the test of time and pressure. Hot stretch reducing high-frequency welding steel pipe after heating to go through the whole, the overall annealing temperature of 800 degrees, and then open the change process, after which a series of processes, the weld and the parent organization performance - has been the same for the complete melting one, well done from the seam to a seamless transition.

Transverse crack after lsaw steel pipe measures rework appear, specifically:

1. Confirm defect

All welds 100% UT inspection, crack marked location, length, depth and direction. If the entire weld has defects, the proposed dig out the entire re-submerged arc weld, partial repair is recommended SMAW.

2, Planing preheat

Preheating temperature is 110-170 ℃, preheating temperature weld both sides of the detection position is not less than 150mm, the heating is within the range of from defects around 500mm.

3, Gouging

Gouging out both ends of the range of cracks, weld integrity is not less than 50mm Outbound middle gouging, gouging ends gently to smooth the transition, the transition surface and a vertical line at least greater than 45 °. Gouging carbon rod angle should be at 60 ° or less, particularly in the crack to arrive at an angle as small as possible.

4, Polished

Polished to no black, polished surface after the transition should be smooth, there should be no sharp pit.

5, PT

After cooling to an appropriate temperature do penetrant testing (PT).

6, Polishing

PT based on test results, for grinding, grinding to no red line so far.

7, MT

After grinding to do magnetic particle testing (MT), confirmed that no residual crack, or should continue to polish until the MT is not detected until cracks.

8, Preheat

Recommended preheating temperature is 110-170 ℃, preheat temperature detection position of both sides of the weld is not less than 150mm, 500mm weld heating within the range of distances.

9, Welding

Welding operations carried out in accordance with the instructions, the bead width not exceeding 15mm, can lanes on the lane. Can SMAW or automatic submerged arc welding process.

10, After welding, insulation, slow cooling

11, Post-weld heat treatment

PWHT is mainly diffusion of hydrogen, lower residual stress after welding for stiffness weldment have devoted to "eliminate the hydrogen treatment," "stress relief heat treatment." Recommended heat treatment system are: immediately after completion of welding heat to 200 ℃ with a ceramic blanket, power off after slow cooling insulation 2h.

12, After the welding detection

After welding is completed 48h, according to the requirements of NDT inspection to confirm repair qualified.

In addition to large-caliber lsaw steel pipe as a structural material generally has good mechanical and process performance, but also has the use of stainless steel corrosion environment, maintaining the appearance of fine excellent characteristics, but also with acid and alkali resistance, high stainless steel pipe temperature, low temperature resistance, excellent magnetic properties, wear and other functions. Stainless steel pipes and other metal materials have been widely used in construction projects also has the following characteristics compared.

1) Large Diameter Longitudinal has a high specific strength and specific stiffness. Specific strength and stiffness of structural engineering in the selection of materials two basic parameters. Strength is the ratio of strength and weight, high-strength steel for the 52 different types of stainless steel pipes in different state than the intensity of the heat treatment may be in the range of 46 to 152, while the aluminum alloy commonly used is 48, copper alloy 17 zinc alloys 16.9. Specific stiffness elastic modulus (Young's modulus) E ratio and proportion of material of high strength steel was 25.5, ferritic stainless steel pipe of 25.6, austenitic stainless steel pipe of 25.3, 25.5 aluminum, copper alloy one of 12.1, 14.1 zinc alloy, stainless steel pipe also shows the structure of "lightweight materials" ideal material.

2) Good high temperature strength and low temperature toughness. Compared with ordinary carbon steel, large diameter longitudinally welded pipes of high temperature performance is much better, so they have better fire performance, common carbon steel at about 400 ℃ loses its load-bearing function, and stainless steel pipe before structural damage can withstand up high temperature of 700 ℃, reportedly suffered 9/11 and the collapse of the US plane hit a skyscraper is due to a large number of aviation gasoline combustion and the temperature is too high resulting in complete loss of load-bearing steel structures function collapse, stainless steel pipe having a good impact toughness, especially at low temperatures more than ordinary carbon steel is much better, you can ensure durability and safety of the building structure, steel structure when subjected to external force (such as collisions, earthquakes, etc.) and curved, structural strength stainless steel pipe becomes very high. Stainless steel pipe manufacturer

3) Good processing performance. Large-caliber Longitudinal plastic, ductile, excellent molding capability, ease of molding, made of thin-walled structures, and can be molded at the same time strengthened, when the structural member after the molding process appear more safeguard its overall performance important.

4) Stainless steel pipe long service life. Depending on the use of the environment, the rational use of stainless steel pipe built engineering structures has a long life, no or very little need for maintenance features, from building life cycle cost analysis, ordinary steel needs an overhaul every 25 years or replace, The large diameter longitudinally welded pipes was Bainiantaiji, compared with the life cycle of various building materials of stainless steel pipe lowest cost, for large-caliber Longitudinal member due to local change and replace, the recycling rate is high, large-caliber Longitudinal itself The recycling rate of up to 100%.

Lamination defect control measures of spiral steel pipe is following below:

1, to improve the toughness of plastic tube

Improve the cleanliness of molten steel, to reduce the harmful inclusions; increase the proportion of the slab crystal axis, to reduce the center segregation and center porosity; the use of reasonable cooling system to avoid cracks occur within the slab; billet or rolling slab to be taken offline slow cooling process, reduce internal stress, thus ensuring the microstructure and mechanical properties of the finished tube and pipe meet the technical standards.

2, the reasonable control of the heating temperature

By measuring the thermoplastic curve, choose the best heating temperature. Note also that there is enough heating tube holding time, in order to reduce and improve plastic deformation resistance and toughness.

3, lower roll speed

Roll speed is a key parameter piercing process, the roll speed from low to high variations in the process, there is a critical stratification began the roll speed. Lower roll speed, easy to form tube bore; higher roll speed, tube and capillary easily form a layered defects. In order to eliminate delamination defects and capillary tube, roll speed should be reduced to the beginning of the critical delamination roll speed or less.

AC electromagnetic coil eddy current testing to the surface of the metal member induced eddy current NDT techniques. It is suitable for conductive materials, including defects in ferromagnetic and non-ferromagnetic metallic material component testing. Since the eddy current testing is not required in the detection coil in close contact with the member, it does not full coupling agent between the coil and the member, easy to implement test automation. But only for eddy current testing of conductive material, it can only detect defects surface or near surface layer, inconvenient to use in the shape of complex components.

When the alternating current through the coil principle, if the voltage and frequency of the use of the same, the current through the coil will also be unchanged. If placed in a metal tube coils, thick-walled spiral pipe circumferential surface induced current, that vortex. Magnetization direction opposite the direction of the applied magnetic field eddy current, so will offset part of the applied current, so that the impedance of the coil, changes have occurred through the size of the current phase. Changes in diameter, thickness, conductivity and permeability of the tube as well as the presence of defects, will affect the impedance of the coil. If the holding other factors constant, only the defect caused by the impedance of the signal extraction, amplification by the instrument and to detect, can achieve the purpose of testing. Eddy current signals can provide not only the size of the defect, while due to eddy current testing can be under a certain phase lag according to the eddy current surface eddy currents on the surface, using a phase analysis can determine the defect of the bit t (depth).

Detection coil eddy current testing, in order to adapt to different testing purposes, in accordance with the relationship between the detection coil and the subject member into through the coil, the coil within the formula and put coils in three categories. For use through the coil when the workpiece is inserted through the coil detector. When the pipe is detected, it is sometimes necessary to coil into a thick-walled spiral pipe internal inspection, it is used within the formula coil. When using put t formula (dot) coil, the coil is placed on the surface of the workpiece is detected checked.

This coil is small, generally with a coil inside the core, high sensitivity, easy to carry, suitable for surface crack inspection of large components and sheet, strip and so on. According to usage detection coil can be divided into absolute coil type, standard comparative coil and self-comparison, three types. Only one detection coil called absolute coil. With two detection coils connected as a differential form, known as the standard comparison coil. Using two coils placed on the same subject in different parts member, as a comparative standard coil, said self-comparison, is relatively standard coil type of exception.

1. Thick-walled spiral pipe forming process, the steel deformation even small residual stress, surface does not produce scratches. Processing of steel in the diameter and wall thickness of pipe sizes range, greater flexibility, especially in the production of high-grade steel thick-walled pipe, particularly large diameter thick-walled tube aspect has the incomparable advantage of other processes to meet more user requirements in terms of pipe specifications;

2. The use of internal and external welding (fine welding) process after the first pre-welding, can be implemented in the best position welding, less prone to the wrong side, partial and incomplete penetration welding defects, easy to control weld quality;

3. Overall mechanical expanding can effectively improve the dimensional accuracy of steel, and to improve the distribution of internal stress of the steel pipe, so as to avoid damage due to stress caused by corrosion, it is also conducive to the construction site welding;

4. Steel pipes need do the 9 items quality inspection with 100%, so that the whole process of steel production in the effective detection, monitoring under, effectively ensure the product quality SAW pipe.

Anti-corrosion insulation pipe with corrosion resistance of steel, and has good insulation properties, has been widely used and promoted in building construction, and constantly improve and spread. Corrosion pipe insulation having different processing types and methods, different processing method to determine the pipe have different properties and functions, and the use range also changes. As the name suggests, it is to increase the number of external spiral steel pipe corrosion insulation class protection, in order to achieve low temperature can be used. In general, the use of second degree pipe insulation inorganic zinc-rich paint, which temperature ≥400 ℃, belonging to corrosion coating, conduit port is used polyethylene film called 3-layer PE or using cold sealing tapes to achieve the previously installed to prevent moisture entering into the water or construction.

Spiral steel pipe insulation for high temperature, water and fuel pumps, chemical pump corrosive. Insulation pipeline centrifugal pump series products with low noise, performance, energy efficient and reliable. The insulation material used is a multi-layer bandaging wrong seam, so it is effective to reduce the heat loss, but also able to control the jacket surface measures to prevent the generation of cold bridges, so that the outer coating of temperature control is guaranteed. Spiral steel pipe wrapped with insulation material multilayer reflective layer of aluminum foil, which can effectively reduce the loss of heat, and can make the steam pipe can be more economical and reasonable. Anti-corrosion steel pipe insulation is a good corrosion resistance, along with good insulation properties, has been widely used and promoted in the design and construction, the current and constantly perfected and popularized. Spiral steel also have different types and methods of processing, while the different processing method to determine the pipe have different properties and functions, and range will change!